Testing IMATEST

Every optical component, optics assembly or electro-optical module is tested prior to shipment. We define the ATP (acceptance test procedure) and the ATR (acceptance test report) documents with pass/fail criteria.

ATP and ATR are defined for both FAI (first article inspection) and for mass production stage.

In addition to the testing done at the factory, we verify and test a portion of the manufacturing batch according to ISO’s standard and perform an internal detailed test report.

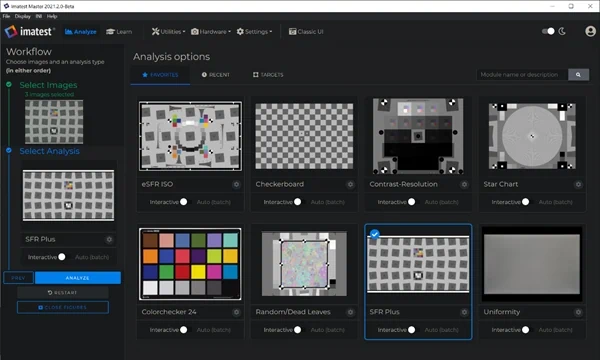

For a custom optics assembly or Electro-Optics module we design and manufacture the testing JIG. We first install it in our lab and once it is approved, we duplicate the testing JIG to the production line. A key element to analyze and to benchmark cameras in our testing set-up is the IMATEST software and hardware equipment.

ATP and ATR are defined for both FAI (first article inspection) and for mass production stage.

In addition to the testing done at the factory, we verify and test a portion of the manufacturing batch according to ISO’s standard and perform an internal detailed test report.

For a custom optics assembly or Electro-Optics module we design and manufacture the testing JIG. We first install it in our lab and once it is approved, we duplicate the testing JIG to the production line. A key element to analyze and to benchmark cameras in our testing set-up is the IMATEST software and hardware equipment.

The Imatest Difference

Developed by experts and used in a wide variety of imaging industries, the ISO requirements have good reason to be the standard. However, technology is rapidly advancing, and ISO standards are slow to adapt to ever-evolving camera capabilities.

Imatest’s software solutions and SFRplus test charts build upon the ISO standards so that our customers have the most capable image quality testing available. We’ve built upon what works and omitted aspects that don’t benefit objective camera quality testing.

- We iterate our software frequently with new updates based on customer feedback

- Our experts are available to answer your image quality testing questions

- We eliminate bias by providing independent, impartial image quality testing for both design and manufacturing

- Our core technology was built to simulate the human visual system, so you can be certain that you’re testing the aspects of your systems that matter most to your customers

Developed by experts and used in a wide variety of imaging industries, the ISO requirements have good reason to be the standard. However, technology is rapidly advancing, and ISO standards are slow to adapt to ever-evolving camera capabilities.

Imatest’s software solutions and SFRplus test charts build upon the ISO standards so that our customers have the most capable image quality testing available. We’ve built upon what works and omitted aspects that don’t benefit objective camera quality testing.